This past week I just had my application to a local Maker’s Market accepted. (If you’re unfamiliar with Maker’s Markets, think Farmer’s Market with a little more lean toward the things that you make.) One of the products that are on my list to sell is reusable beeswax wraps.

I’m super excited to present this item, not just at the market but also here because this is a traditional item that was used before the convenience of plastic that will it doubt come into popularity again.

There are so many reasons why you might be interested in how to bring a reusable wrap into your home. Maybe you’re budget is tight and $5-20 saved in a grocery trip means something to you. Or your family could be one who is looking to reduce the amount of plastics that are used and thrown away in your home. Perhaps you or a loved one is facing a health moment that requires you to reduce the amount of chemicals that are used in your home. Or maybe there is another reason that stands out in your mind.

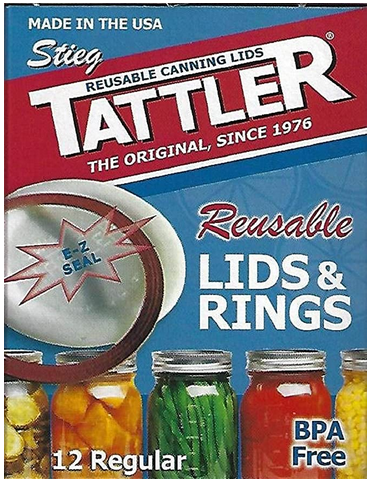

Beeswax reusable wraps can meet those needs and many others because it’s made from very few ingredients; 100% cotton or linen cloth and beeswax are the two items that you have to have to make this. I also include pine resin (for additional tackiness) and jojoba oil (for flexibility that prevents the wax from cracking)

Originally I wanted to make these wraps for my family because half of our glass bowls do not have lids. And all of our lid bowls always seem to be in use and unavailable when we need something with a lid. So I have more usable bowls, but I can also meet other needs in my kitchen: my homemade bread won’t dry out on the cut end, less chemicals are being transferred into our left over foods, takes up less space than Tupperware, and easy enough that my kids can use them.

While listening to others who’ve been making these for years, I learned about a few other beneficial features. When the wax wears thin, these wraps have not met the end of their life. You can reapply the wax (or wax/resin/oil combo) and 5e wraps are just like new. But if the cloth itself becomes damaged, the wrap can be composted because there are no synthetic materials that are used.

How to make or revitalize a previously used wrap

There are a few different methods of making these. So please don’t think there is one way. Find a method that works for you and makes sense with the resources that you already have available in your home.

The oven method. You place your cloth on a cooking sheet, with your wax of choice (plain beeswax or a beeswax combo) scattered across the top of the cloth. Your cooking sheet is placed in the oven, around 200 degrees F, until the wax melts. You then use a brush and make sure to spread the hot wax evenly across the cloth.

I did not use this method because none of my cooking sheets have a lip on them. So I would end up having wax in the bottom of my oven. And I didn’t want to buy new cooking sheets just to have them for crafting. I don’t have the space to store them or the money to buy them. So I went with a different method that I already had the resources for.

The water bath method: I used one of my small saucepans and filled it halfway full with water. I pulled out a hot water safe container to put my wax combo in, and then set that inside the saucepan. It took a bit of time for the water bath to melt my beeswax and pine resin, but that step was a success. What didn’t work for me was pouring the wax combo on the cloth or dipping the brush in and brushing the fabric. This method was a fail for me because my brush clotted with the wax as it cooled. There was no way to warm that up to turn it back into a liquid or to clean my brush. I know some homesteaders who love using a brush when making beeswax wraps. I’m not one of those people. But I did try it.

The Ironing method: I’m going to walk you through the steps of this method below. This one takes a few additional manufacturing items to make. But once I was set up I didn’t have to prep anymore. And I kept making wraps until I ran out of one of my ingredients. This is not a zero waste method. However it is the method that minimizes the loss of wax ingredients and is the easiest to clean up.

Prepping for the Iron Method

Before setting up my work table, I needed to get my ingredients ready.

I buy my beeswax from local bee keepers. That means I generally get the wax in a brick form. And whether I’m using the wax for wraps or other products I make, I have to great it down to make the melting process a little quicker.

Foraging pine resin is on my to-do list. I have not done that yet. So I purchased pine resin. It arrived in a bag of crystalline chunks. Resin takes a higher heat to melt than beeswax, so I needed to crush the resin to minimize its melt time. The quickest way to do this is put some resin in a paper bag and hit it with a hammer until the resin becomes as small as you want it. (Powder is ideal for this method.)

What I learned when crushing resin— when you hit it properly with a hammer, the resin is going to break through a paper bag. If you use the wood handle you keep the bag pretty much intact, but the resin is let going to turn all the way into a powder. But if you use the side of the hammer (the largest flat surface of the metal portion of the hammer head) you maximize the amount of resin turning into power with very little resin escaping out of a crack in the bag.

With the ingredients ready to go, the next step is to set up your work station. Half the videos I watched had crafters working on exposed countertops. I DO NOT recommend going that route. The short story is that the wax combo got on my table. Fortunately I have my tricks to lifting wax off of my table. And I will not be doing that again!

So learn from my mistake and find an old towel that you do not mind using for crafting purposes from here on out. Shop rags are amazing for this. I just didn’t have any that were large enough for me to make my Rage wraps on top of. So I decommissioned a towel.

Since I knew I was going to work on my large wraps, I grabbed that size of cloth and set it on my towel. From there I sized out 2 long sheets of parchment paper with a few inches of over hang on all sides. (Your wax is going to spread and needs this buffer to keep the wax off your iron.)

The wax is going to slide through the sheets of parchment. To prevent this I taped my sheets together. This time I used a packing tape. And once I taped the parchment together, I flipped it over so that the tape side was down on the towel.

I placed the cloth that I’m making the wrap out of on top of this bottom sheet of parchment. Then I made a second double sheet of parchment to place on top of the fabric. This time I kept the tape side face up. And to keep the iron from melting this tape, I placed one single sheet of parchment over the tape.

Now it’s time to make a wrap!

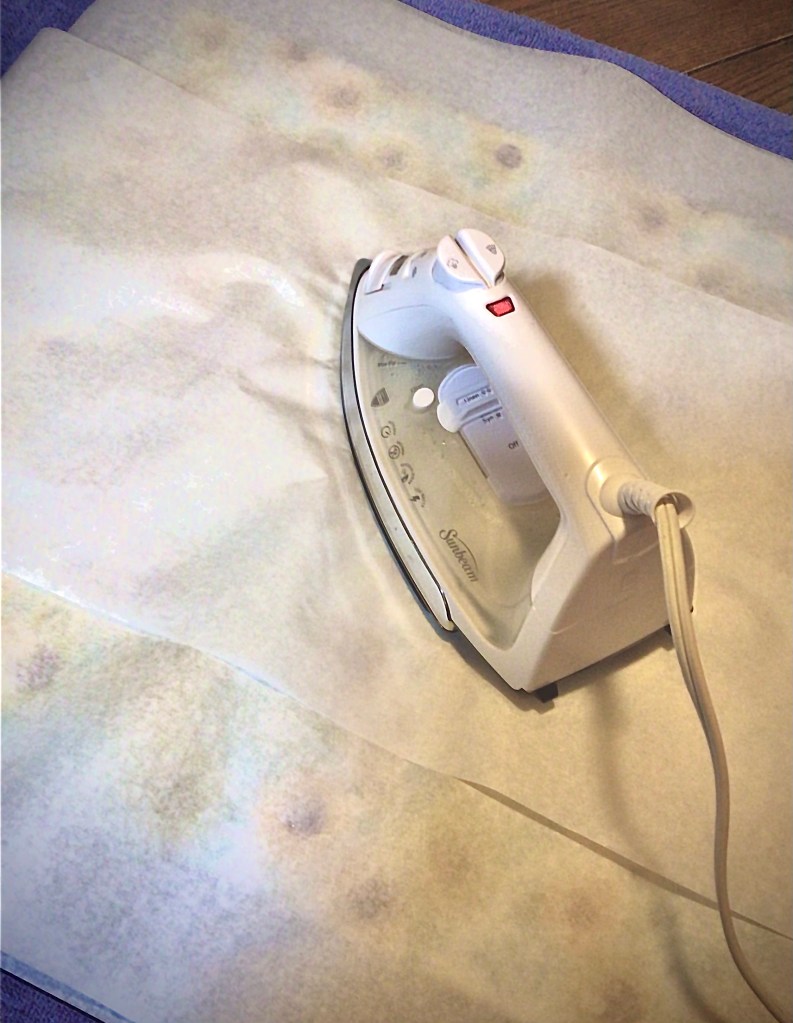

Preheat a clothing iron to the highest/linen setting. Even if you’re working with cotton, don’t be afraid to use the highest setting. The wax, and especially pine resin, needs the heat to turn into a liquid and for you to work quickly.

In a cup I weigh out equal parts of beeswax and pine resin. (If you’re making just beeswax, there’s no need to measure the ingredients unless you figure out the precise amount of wax you need for the size of cloth you’re working with.) Then sprinkle your ingredients all over the face of your cloth.

Cover with the top layer of parchment paper and start to iron.

If you are using resin, and used some small shards instead of all powder, you will want to show patience up front here. Set the iron down on top of the stones and wait while the resin melts. If you immediately glide your iron back and corn, the resin shards are going to rip the parchment and then all the waxes are going to end up on your iron face.

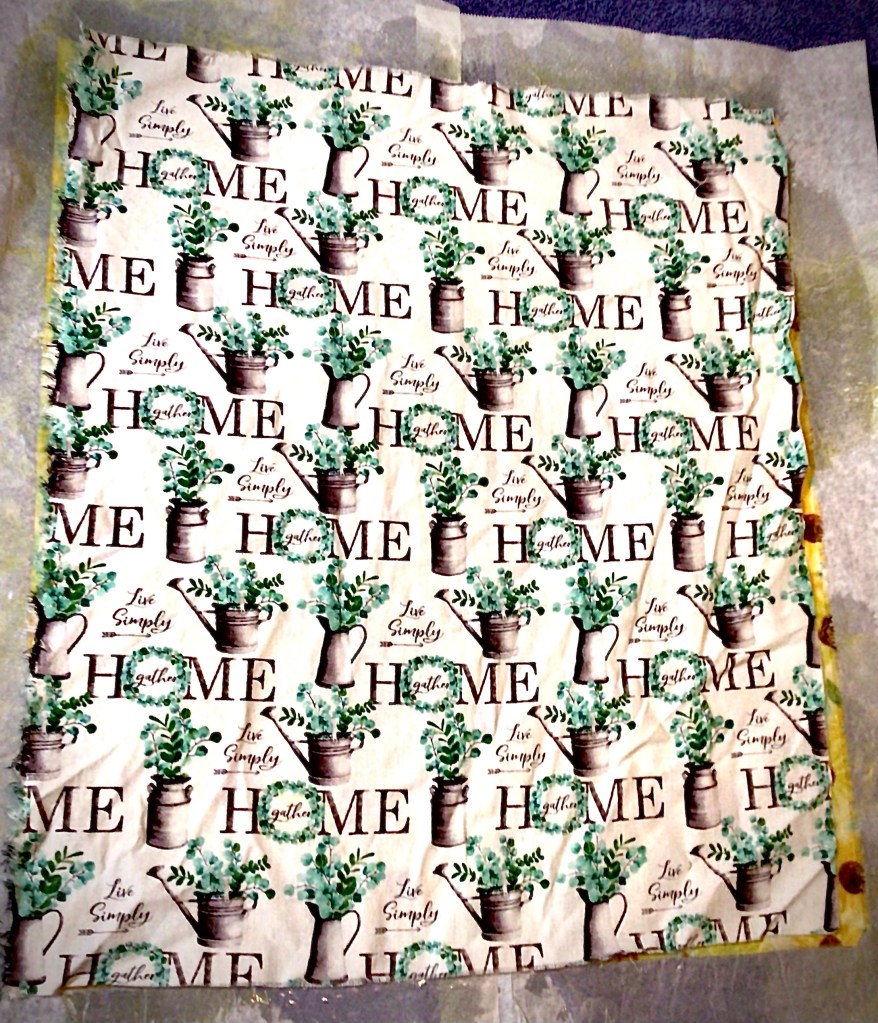

As you can see in this middle picture, below, you will see your waxes through the parchment. This is useful because you will get a general idea of where the wax is in comparison to the edge of your fabric. Work in the center and push the wax out to the edges.

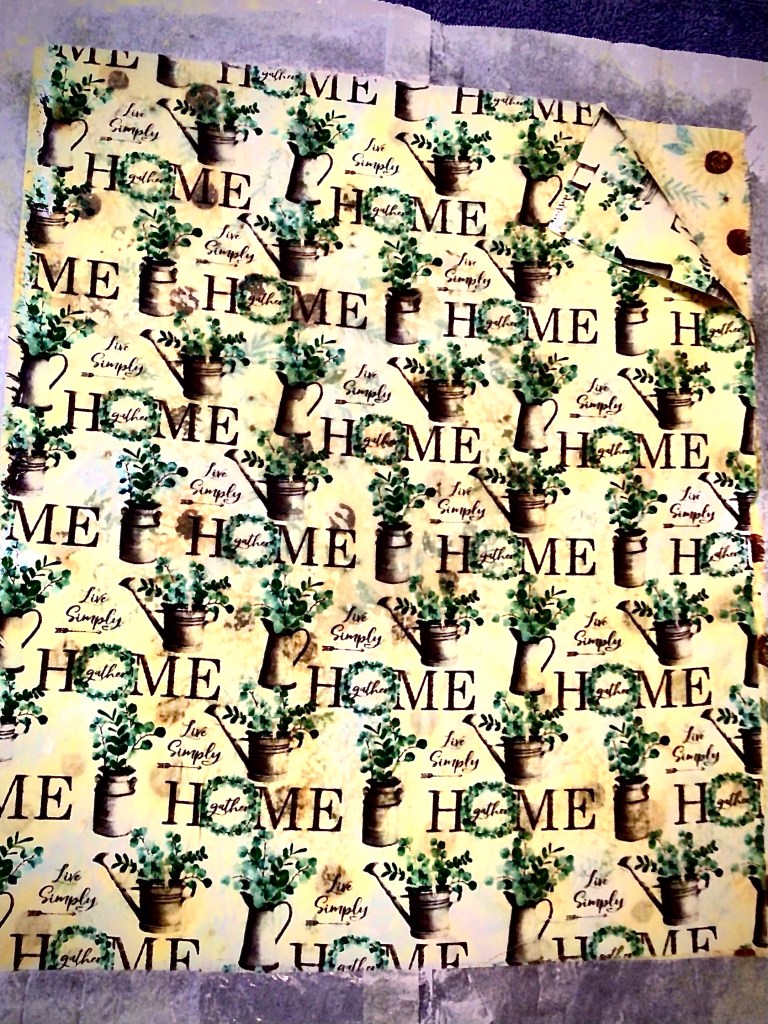

There will come a moment when you think you have the wax spread over all the fabric. Lift the parchment and take a quick leak. No matter if you’re working with light or dark fabric, you will be able to notice where I here are patches of fabric that have not been covered with wax. In the third picture above you will notice the white fabric that has obviously not been covered by the yellow tint of the beeswax.

If there are still pools of was on the cloth, lower the parchment paper and use the iron to push the wax over to those blank spaces. If the fabric seems a bit “dry”, with no extra wax to move around, add a little bit more wax over the dry spots, lower the parchment, and melt the wax into place.

Once you’re satisfied with your coverage, take a look at the amount of wax present. You want just the right amount where the fabric has a matte like finish too it. If it’s shiny or has pools of wax, you will want to absorb that excess wax off. You can do this by placing a new piece of fabric on top, lowering the parchment and ironing over the entire surface of the new cloth. Once all the excess wax has been absorbed, you can pull out the first cloth (and leave the second cloth to add more wax to any dry parts.

When a cloth is finished, pull it free from the parchment papers, hold it by the corners and wave the cloth back and forth. You want to cool down the wax before you set it on something to finish drying. (I use chair backs.)

A Pine Resin Problem to be Aware of

One bit of information I didn’t hear from anyone is a potential problem to look out for when working with pine resin. If there is a spot where the resin is not in equal parts with the beeswax, it’s going to act like glue to the parchment paper.

The first sign of this is when you go to lift the parchment paper and it feels like it’s locked in place. You didn’t do anything wrong and nothing is ruined. All you have to do is iron over that spot. When the resin is hot again, you can lift the parchment paper and it won’t be stuck anymore.

If you try to force the peel, the parchment will rip. And if you’re not done making wraps, you will want to take a new sheet of parchment to cover the holes and rips. It’s just easier to get the resin hot again and then peel the parchment back in one piece.

Caring For Your Reusable Wrap

Everything about a beeswax wrap is oil based and meant to manage moisture. It keeps food moisture in and humidity out. Because of this feature, you absolutely do not want to use a grease fighting detergent when cleaning a wrap after use. You can use a gentle soap and the wrap will be fine. However grease lifting detergents are going to break down the wax and fat molecules in the wrap, which in turn will wear down the wax and make it less effective in holding to itself and your kitchen equipment.

Remember, we used heat to set the wax on the cloth. Hot water will warm up the wax and makes it easy for the wax to be removed from the fabric. So when you wash or rinse off a beeswax cloth, keep the water tepid. By keeping the water temperature cool, you will prolong the life of a beeswax wrap.

There are some things that you absolutely do not want to do with a beeswax cloth:

- Do not use in a microwave.

- Do not clean in a dishwasher.

- Do not leave onto of a heat source (in a hot car, on a sunny and hot windowsill, on any heat source).

- Do not use to store raw meats.

- Do not use with hot foods. Cool them down safely and then cover cold food with a beeswax wrap.

- Do not leave in standing water.

When properly maintained, beeswax wraps are absolutely safe to wrap your foods in. Beeswax has antimicrobial properties. Depending on how you care for a wrap, it is possible for one to last a year or several.

A Couple Ways to Use a Beeswax Wrap

As I mentioned before, I wanted these to use on bowls that I do not have lids for. In this example I have a standard glass coup bowl and my small wrap. Simply place the wrap over the bowl. Then press the wrap down much like a sheet of press and seal food wrap.

The heat from your hands is what softens the wax. Its tacky nature naturally sticks. To be fair, the wrap sticks better to itself over the smooth edges of a glass bowl.

I found that just pressing the wrap down formed less of a seal and more of a fitted cap of a lid.

For better results, crease the wrap and seal it on itself. As in the case of this bowl, the folding of the fabric and making it taper down the side of the bowl, this tapering down gives the resistance for the wrap to stay firmly secure to the top of the bowl.

But the wrap doesn’t need to have a structure to seal up. You can have the wraps become its own container and never have to buy a sandwich bag again.

Simply lay your sandwich in the center of a wrap and seal it to itself.

In the second picture, I folded the bottom of the wrap up and pressed the fabric down the sided of the sandwich and pressed the fabric into itself to create a seal. The sides I folded over over and the top down.

In this last picture, I wanted to show you that even when I stood the sand which up, it did not unwrap himself at all!

Again, these are only a couple of ideas on how to use these. Another idea is on a hiking trip. If you forgot to bring a foraging container, but saw something you wanted to gather, you could pinch together the sides of a wrap and make a little basket.

This is genuinely one of those kitchen utensils that have many uses and are user friendly.

For those of you who are local, come by the Maker’s Market on October 7th and you can play with the demo wrap and see just how user friendly these are!

Leave a comment